What is Supply Chain Risk Management (SCRM)?

Before coming to SCRM we must have a clear view about supply chain and supply chain process. This will provide us an easy route toward SCRM.

What is Supply chain?

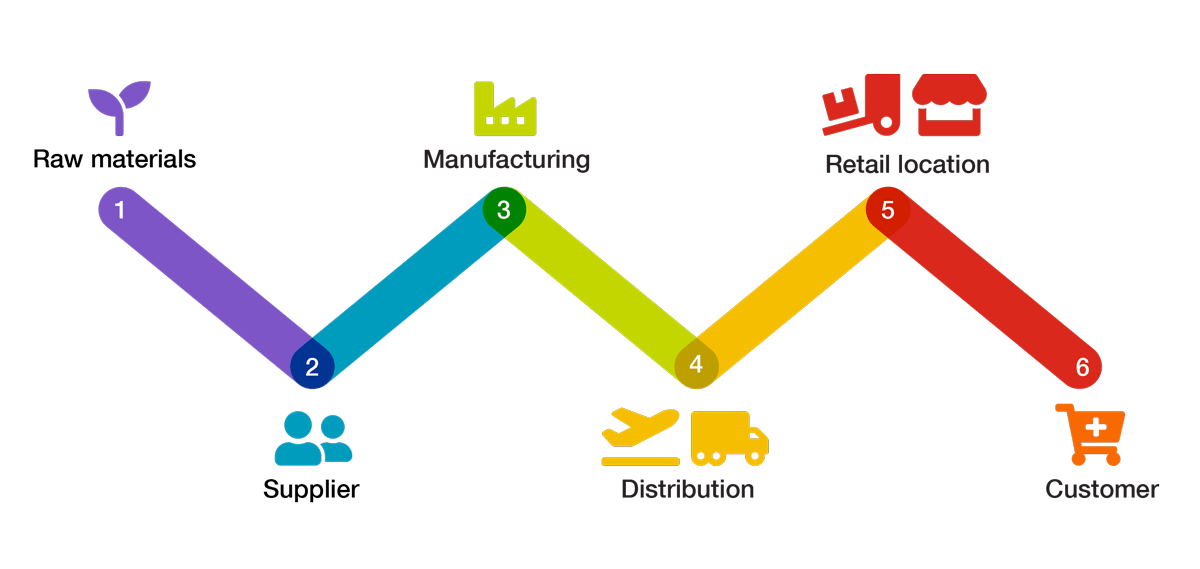

Supply chain is essentially concerned with the systematic integration of product flow, cash flow and information flow between producer, supplier and customer. It is complete ecosystem of producing and delivering a product or service from initial stage of referencing the raw materials to the final consignment of the product to customers/clients.

One of the most censorious steps in analysis and strategic planning is mapping out of supply chain across multiple supplier tiers. It is of much importance for every firm because it helps in developing insights about others involved in the business and their contributions. It determines which factors are beneficial and productive for company. The main objective of supply chain management (SCM) is delivering products to clients by saving costs, time and company’s resources. It helps in developing proactively strategy for the future that on which factors they rely on and to whom party, they should collaborate. As supply chain is extensive and complex system so there the occurrence probability of risk is high, every industry wants to mitigate or manage these risks so that they may preserve themselves from big disaster.

Many organizations are additionally involved regarding their supply chain risks. These risks include internal threats, natural disasters as well as external threats.

Internal threats:

- Defective products

- Emergency situation like fire-caught

- Labor strikes

- Complex processes

- Lack of technical knowledge

- Poor performance of sub-suppliers

- Loss of patent rights etc.

External threats:

- Civil unrest

- Terrorism

- Cyber attack

- Utility failure

- Government policy

- Piracy

Natural Disasters:

- Earthquakes

- Wildfires

- Floods

- Storms

What is Supply chain risk management (SCRM)?

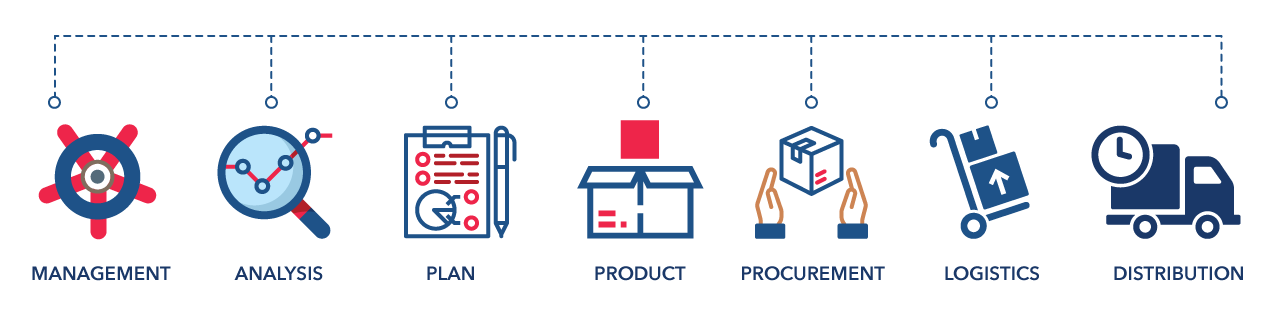

Supply chain risk management (SCRM) strategic planning process of tracking, assessing, mitigating, monitoring and controlling risks all over in supply chain. It combines third-party contributions, with graphical views into company’s supply chain and its logistics. SCRM is a crucial facilitator that is embedded and integrated into the core processes of any company.

Supply chain risk management importance:

SCRM is increasing in importance due to globalization, brand reputation, new technologies and increasing threats. SCRM is an enterprise value driver. SCRM focuses on the implementation of strategies in managing every-day and occasional risks on a nonstop basis, with the target of reducing susceptibility via cooperative approach and making certain continuity if risks occur. SCRM consistently identifies and analyses the key failure points at intervals the supply chain. A secondary objective of SCRM is to not solely mitigate financial and reputational risks however to conjointly increase price at intervals the supply chain through improved performance.

The Supply chain Risk Management Lifecycle/ How Supply chain risk Management works:

Supply chain risk management works in multistep process like Risk Identification, Assessment & Evaluation, Selection of appropriate risk management, Implementation of supply chain risk management strategy, Mitigation of supply chain risk, Risk monitoring and controlling.

1. Risk Identification

It is the process of identifying hazards and associated risks (country, sectoral, tiers risks). It facilitates a good understanding of the companies involved across the supply chain. Identify suppliers and locations, identify all tiers not only suppliers, identify contractors and service providers. It is important for the completeness to ensure that interfaces between processes are also well known as this is where problems may easily go undetected. All this determines what types of risks are we exposed to and where are they in our supply chain? Information to support risk identification can come from various sources like internal and external factors throughout supply chain, known deviations, complaints, audits (Internal and external), components of the process under assessment (people, premises, equipments, materials, quality assurance & quality control (QA/QC) and services etc.

2. Assessment and Evaluation

Understanding of supplier profile, workforce profile and commercial relationship and how much these risks financially impact on your business. Be aware of those partners/stakeholders whose role and contributions are crucial to your sales, margins or profit. Rank by severity and likelihood and consider leverage of these risks. It is decision analysis, case study(s) and perceptions-based process. Some key areas for risk assessment.

- Feasibility of reliable supply

- Most effective allocation of resources

- Probability of demand

- Probability of success of new product launch

- Market growth

- Opportunity costs for decisions

Risk evaluation uses both qualitative as well as quantitative scale to determine the significance of the risk. A process that organizes the information from risk assessment to make decisions for risk reduction. Investigate particular situations, analyze root causes, make actions and timelines for suppliers and for clients/customers as well.

3. Selection of appropriate risk management and its Implementation

Risk management is an effective means of selecting mandatory controls. To do this requires complete visibility about supply chain and all the organization involved in it. A project management approach provides structure, control and assignment of resource, and is fully used by many organizations. Then the activities of organizations in supply chain should be reviewed to identify what is critical to the product and what could go wrong.

Enablers of risk strategy implementation: complexity management, organizational learning, information technology and performance metrics. Apply supply chain risk management strategies though which we quickly recover from a disruptive event and return to normal operation. This implementation will help us in mitigating risks.

4. Mitigation of supply chain risks

“Alleviation of danger or threat in a project.” Risk mitigation encloses loss prevention, loss control and claims management. It’s the project management team who is responsible to mitigate risk. It performs a radical analysis to cut back the probable threats and vulnerabilities. Everyone involved in a project team wants to mitigate risks and produce rewards and revenue outcomes. If risks are not maintained, budget and time both will overrun and will cut profit margins and damage personal as well as company reputations.

Define your active and passive approach to mitigate risks, prepare yourself and your workforce for unseen risk events. This will provide you a foundation to address risk and taking significant measures to resolve supply chain risks and shield your brand.

5. Monitoring and Controlling supply chain risks

This method ought to be created to trace potential risks, supervise the implementation of risk plans, and assess the effectiveness of risk mitigation procedures. This process works throughout the project duration and gives us overall performance of the project.

Risk control encompasses the decision-making activities that results in actions (Risk Mitigation) and supply chain reviews. Supply chain review includes changing control and notification suppliers, control of second or further tier supplier via specifications, sampling/ testing/ verification, methods of measuring performance, correction, reworking, investigations, traceability (process, product, equipment, operators), inventory control etc. The main objective of controlling is to reduce risk to an acceptable level and not to grow up further. Controlling efforts must be proportional to the significance of the risk.

Key Solution:

Solution:

Customize to your Business and Industry, taking your company challenges into account. Engenius (Executive Education) is a platform that is providing and facilitating employees as well as individuals with such training and programs for an organization as well as personal development. An unconventional approach to learning – project-based & experiential, assessments & group presentations. Proven track record of delivery, and not matched with any other offering in the market. After almost 20 years of executive learning, Engenius focuses on poignant and impactful leadership skills, personalized learning, and precise and measurable growth. Find us more on our official website: https://engeniusonline.com/